Boat painting

Painting services to renovate, protect and improve boats performance.

Marine paints, antifouling, or silicone prescription and application.

Boat appearance defects correction.

Ship element restoration and preservation : hulls, tanks, hulls, propellers, decks, fittings, parts, etc.

Protection against corrosion by ACQPA Level 1 and 2 certified painters.

Metal painting work validated by a FROSIO-certified firm.

Naval Painting: A Shield Against the Elements

BLASTAIR provides a comprehensive marine paint system. Its goal: to extend the life of a boat, beautify it and improve its performance. The offer includes a variety of preparatory treatments and access to painting and sanding booths.

Tailor-made support is offered from project initiation to delivery. Project monitoring continues until delivery. This transversal approach to painting guarantees a final treatment that complies with the recommended manufacturers standards.

Naval vessels protection : improved longevity

Painting a ship forms a protective layer on the treated surfaces. This protective layer shields the boat’s structures from external elements:

- salt water

- UV rays

- marine organisms

This protective film prevents osmosis and corrosion, extending the durability of boat components:

- gray / fresh / black water tanks

- hulls

- boat propellers

Naval painting of hulls, keels, tanks, and boat parts

Marine coatings serve various functions, such as improving speed and fuel consumption. Maintain and strengthen your defenses. Etc.

Naval paints are chosen based on the surface type and desired results:

- Protective primer

- Undercoat

- Coating

- Epoxy

- Anti slipping

- Antifouling and propeller performance (PROPSPEED)

The naval paint type to be applied is selected for its effectiveness and durability on a boat hull or a navigation element.

Antifouling

Antifouling treatment application maintains hull efficiency and longevity. This preventive treatment combats the marine organisms accumulation: algae, barnacles and other biofouling forms that adhere to a boat hull. By preventing this accumulation, the antifouling coating also protects against osmosis, which damages structures in the long term.

A good antifouling coating also improves a boat hydrodynamic performance. In fact, keeping the hull smooth and biological free growth reduces its water resistance. Navigation is therefore faster and more fuel efficient.

The antifouling type is recommended depending on the boat type, the hull materials, as well as the navigation conditions and the waters frequented.

Specific Boat Hull Painting

Two-component marine paint increases resistance to external aggression. While a one-part paint includes the hardener, two-part paints are mixed before application. The provided coverage, grip and protection above and below the waterline are maximum.

Anti-Slip Solutions

Anti-slip paint is applied for onboard safety. Once painted, bridges and other risky areas’ slippery parts adhere.

Pre-treatment preparations: a complete painting system

After coating selection, pre-treatment preparations contribute to the final treatment quality.

Preparatory treatments

Our comprehensive painting system ensures compliance with recommended paint supplier standards. Surface preparation steps include:

- Measuring porosity, humidity levels, and support condition

- Calculating paint coats and drying times

High-performance paints

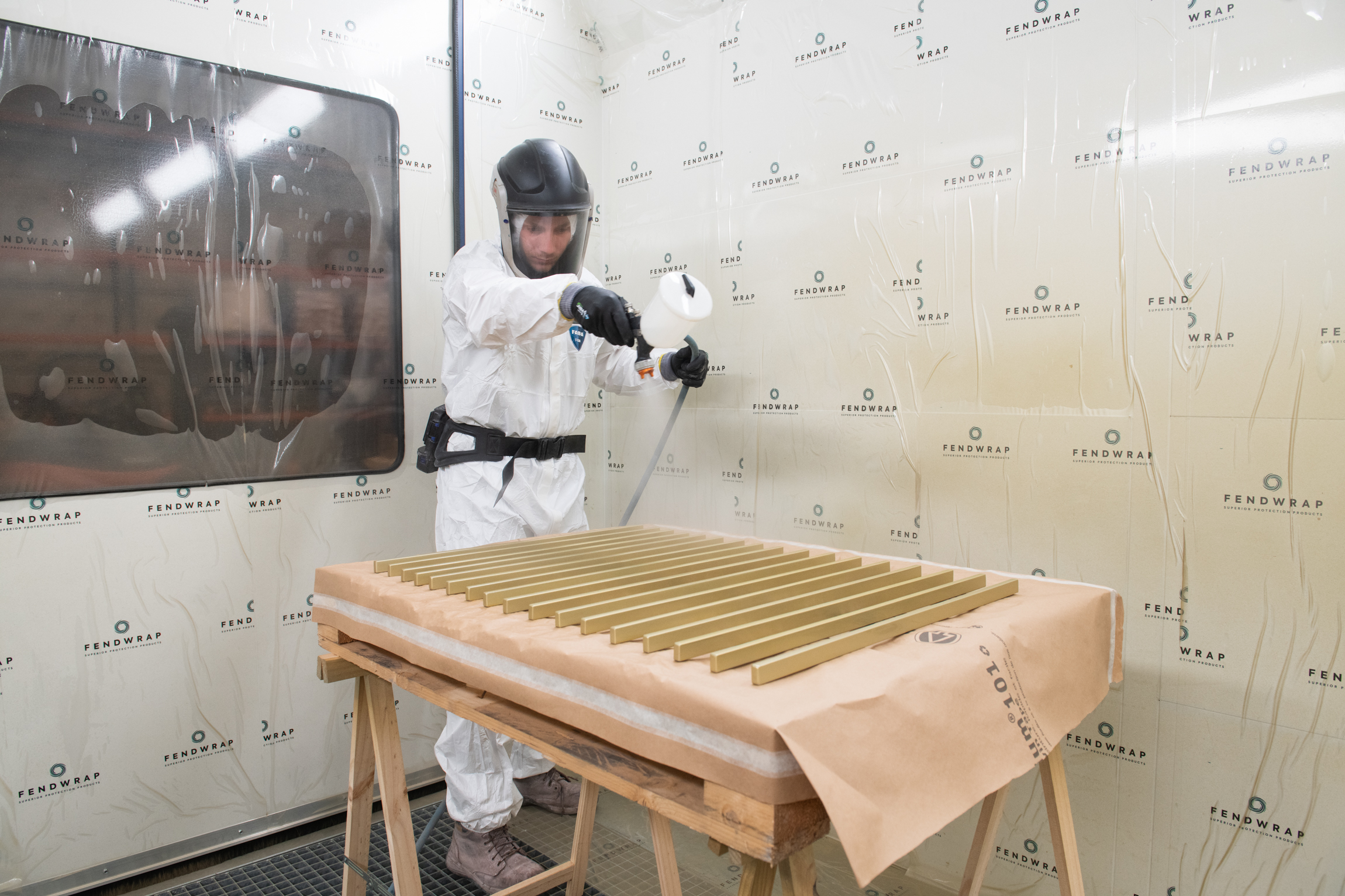

After defining the suitable covering product and preparing the support, the painters determine the high-performance treatment to apply the layers: spraying with a gun, application with a brush or others.

Painting Boat Parts by Powder Coating

Painting boat parts with powder coating enhances resistance to maritime conditions. This method resists chemical and physical attacks from the marine environment. It protects the fittings against corrosion and wear.

In addition to durability, powder coating takes care of the boat’s metal elements aesthetics. This superior level of finish guarantees metal parts shine and protection.

Certified treatments

ACQPA Level 1 and 2 certifications attest to expertise in anti-corrosion treatments. They certify compliance with the highest work quality standards in the metal painting industry.

Quality control by a FROSIO-certified firm validates each metal paint. It includes the evaluation of the degree of roughness and resistance to salinity.

Boat Painting: A Tailored Approach to Ship Renovation and Protection

A tailor-made painting program is provided for each project: two-component boat paint, fiberglass hull, or other.

Estimate the painting of a ship

Our support extends from pre-treatment preparation to confinement and scaffolding installations.

Personalized support is provided throughout the intervention with a single dedicated contact.