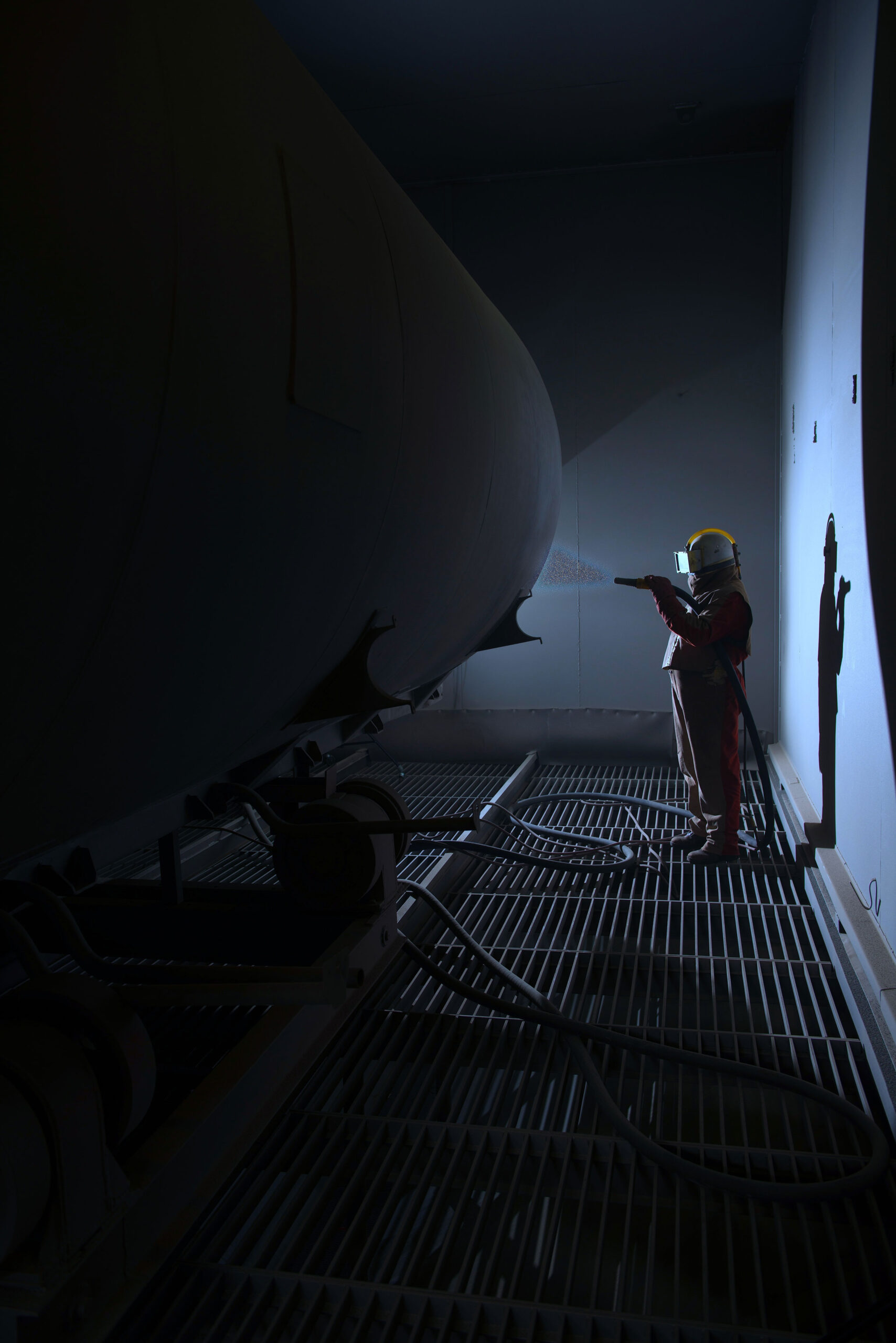

Boat sand blasting / aero blasting / hydro blasting

For boats, yachts and super-yachts hulls and surface preparation, BLASTAIR provide a range of blasting technologies :

- Sandblasting: High-speed sand blasting on a surface to be stripped.

- Aero blasting: Derived from sandblasting. Low pressure projection of an abrasive.

- Hydro Blasting : Derived from sandblasting. Low pressure projection of an abrasive with simultaneous misting of water.

Techniques adapted to boat operations

Rapid, ecological, precise and with high efficiency, these techniques perfectly meet nautical constraints.

Boat sandblasting

Sandblasting, aeroblasting and hydroblasting respect the specific materials used in the boating industry, while allowing efficient stripping and deoxidation as part of a “refit & repair” program for your vessel’s hull. Depending on the treated surface and the type of stripping to be carried out, BLASTAIR offers the most effective abrasive means for your yacht or superyacht.

Hulls

Rigid or semi-rigid boat hull sandblasting. Keel sandblasting.

Engines

Boat, yacht and super-yacht engine sandblasting.

Preparations

Steel boat sandblasting or paint sandblasting.

Aero blasting

Derived from sandblasting. Low pressure projection of very fine aggregates.

- Boat hull air scrub

- Aero sandblasting of boats (stripping by airblasting).

Hydro blasting

Another method derived from sandblasting. Our hydro-exfoliation work is based on another technique of low-pressure projection of an abrasive combined with simultaneous water misting. Allows for gentle cleaning and surface refurbishment. Allows you to combine the exfoliation technique with that of airbrushing.

Techniques adapted to boat operations

Rapid, ecological, precise and with high efficiency, these techniques perfectly meet nautical constraints.

Depending on the treated surface and the type of stripping to be carried out, BLASTAIR offers the most effective abrasive means for your yacht or superyacht.

Sandblasting, aeroblasting and hydroblasting respect the specific materials used in the boating industry, while allowing efficient stripping and deoxidation as part of a “refit & repair” program for your vessel’s hull.

The ideal solution before an epoxy paint or anti-corrosion treatment

In yachting and shipyards, sandblasting is widely used to remove an antiquated antifouling and prepare the hull for a new treatment and a new epoxy paint.

Indeed, the sandblasting method allows a surface layer pickling while preventing damage to the underneath surface. It also eases the new paint attachment by leaving the hull slightly porous.

After a sandblasting operation, the treated surface is ready for a new antifouling, paint or varnish application.

An equally effective solution to combat plastic hulls’ osmosis.

These tailored solutions are made possible by our different blasting machine which includes shot blasting (high pressure water blasting, high pressure hydro blasting machine, sand blasting, walnut shells blasting), our methods offers to a boat owner the less time consuming technologies for completely removing any layer (gel coat, anti foul) from his boat.

Blasting methods with variable particle size

BLASTAIR is the promise of a complete tailored service. Therefore, in order to optimize your ship rehabilitation – according to industry standards – our sandblasting operations are carried out according to a variable granulometry. This perfect adaptability provides total control of the pickling force depending on the areas to be abraded.

Estimate a boat sand blasting

Get in touch with our experts and request a free quote.